This type of maintenance is recommended once the on-site oil and electrical tests, require an internal inspection of the windings, tap changer, leads, hot spots, increases in humidity, excessive deterioration or any oil leaks present on the transformer’s structure or radiators that cannot be fixed on-site.

Tradelca S.A.S has a stock of over 250 transformers available for rental and swapping on a loan basis, in the event that the off-site maintenance is required. In this way the clients electricity supply is secured whilst its transformer is repaired.

The following services are available for off-site maintenance:

OIL CHANGE

If the deterioration of the oil is excessive, and oil regeneration with Fullers Earth is not worthwhile due to the amount of Fuller Earth needed, an oil change is recommended. The oil change consists of initial electrical tests, tank oil drainage, extraction of the active part, and rinse of the windings with new oil to remove sludge that causes blockage to the refrigeration ducts, drying of the active part in an specialized oven, gasket change, re-tanking of the active part, new oil fill, paint and final testing.

OIL REGENERATION

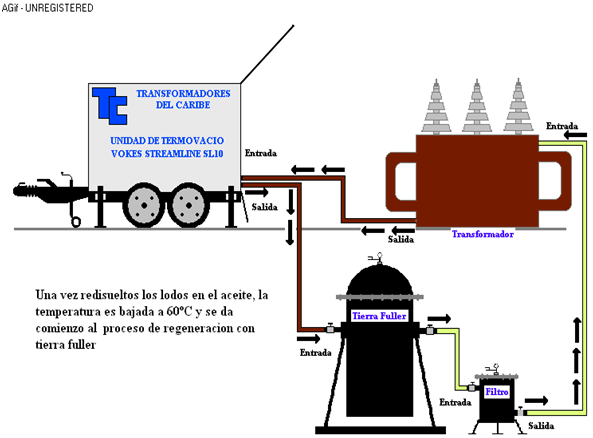

Oil regeneration is recommended when the acid number is higher than 0.06 mgKH/g, Interfacial tension is below 27.9 mN/m and the ASTM color is above 4.0. The process of regeneration is done with Fuller Earth Ultra Clear 30/60 heated up to the aniline point, redissolving sludge in the oil once again. If the transformer oil, at the aniline point, is recirculated various times, the oil will clean the windings, clamps, core, tap changer etc. Once this cleaning process is finished, the oil is transferred to the tanks filled with Fuller Earth. This process removes a great part of the decomposition products of the oil, polishes and restores the oil to "as" new. (see diagram):

Fuller Earth tanks – regeneration equipment.

Oil Purification

One of the main causes of premature deterioration in transformer oil is the presence of water, which can enter the transformer due to many reasons: bad gaskets, fissures in the transformer tank or radiators, oil leakage, preservation systems in bad condition (silica gel or damaged membrane) and poor filtering from factory or in during the final assembly on-site. If the oil is contaminated, it means that the humidity and solid suspended particles, excluding oxidation products, will require oil filtering through thermal-vacuum (reconditioning), which removes the impurities mechanically.

THERMA-VACUUM DRYING:

Off-Site Manintenance

Off-site maintenance // Oven no. 1 with capacity for transformers from 3 MVA up to 30 MVA

Oven no. 2 with capacity for transformers from KVAs up to MVAs

Oven no. 3 with capacity for distribution transformers.

Off-site maintenance

Disassembly of a 25 MVA transformer, 110 kv/ 230 kv using a 40 ton overhead crane

Off-site maintenance

110 kV Bushing Testing with Doble M4000

Off-site maintenance

Testing of a 25 MVA 110-23KV transformer before oven drying

Off-site maintenance

Reception of a 30 MVA 110/23 KV, 38 ton transformer.