Tradelca S.A.S takes advantage of the technological advancements on insulating materials in order to fully exploit the repairs of transformers, whether its dry-type or oil-immersed – mineral, synthetic or vegetable oil -, in order to obtain a reliable and effective result for the electrical equipment. The range of service repairs include inspection, testing, core repair, windings, adjustments, regeneration or insulating liquid change, painting and routine testing.

Our engineers can assist in the evaluation of the problem your transformer may have and recommend the best possible solution.

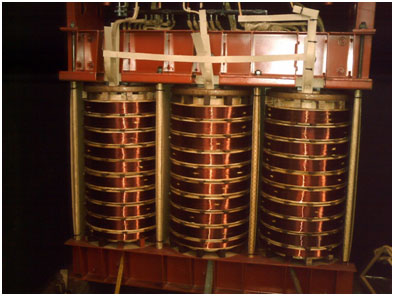

We make continuous-type windings, sections and disc types (see picture):

Continuous type

Section type

Disc types

Our facilities at Tradelca S.A.S have a modern infrastructure and we have experience with the latest technology, that analyses and registers each of the steps for the repair and reconstruction of dry-type transformers of medium and low voltage with a capacity to up to 2000 KVA, 15KV, as well oil insulating transformers up to 50 MVA, 115 KV.

All transformers are tested in accordance with ANSI/IEEE standards and the control of our processes, procedures and tests and inspections give us the confidence to warrant that the work is done correctly from the start to the finish. The management of the oils and the filtering systems together with the quality oil testing laboratory are part of our infrastructure.

Tradelca S.A.S keeps up to date with the latest industrial and technological advancements in order to offer the best alternatives in the repair of transformers.